3D printing changes the rules for product development and production, but that doesn't mean it's perfect. It's not fast, it's actually pretty slow. We think of plastic products being made in seconds or minutes, but 3D prints take hours to days. The surface finish is also a challenge with printing. Each layer of the print is visible and tactile, especially on sloped surfaces. Lastly, gravity makes many features difficult to print. That being said, a 3D printer is just a tool and when the tool is the right hands, magic can happen.

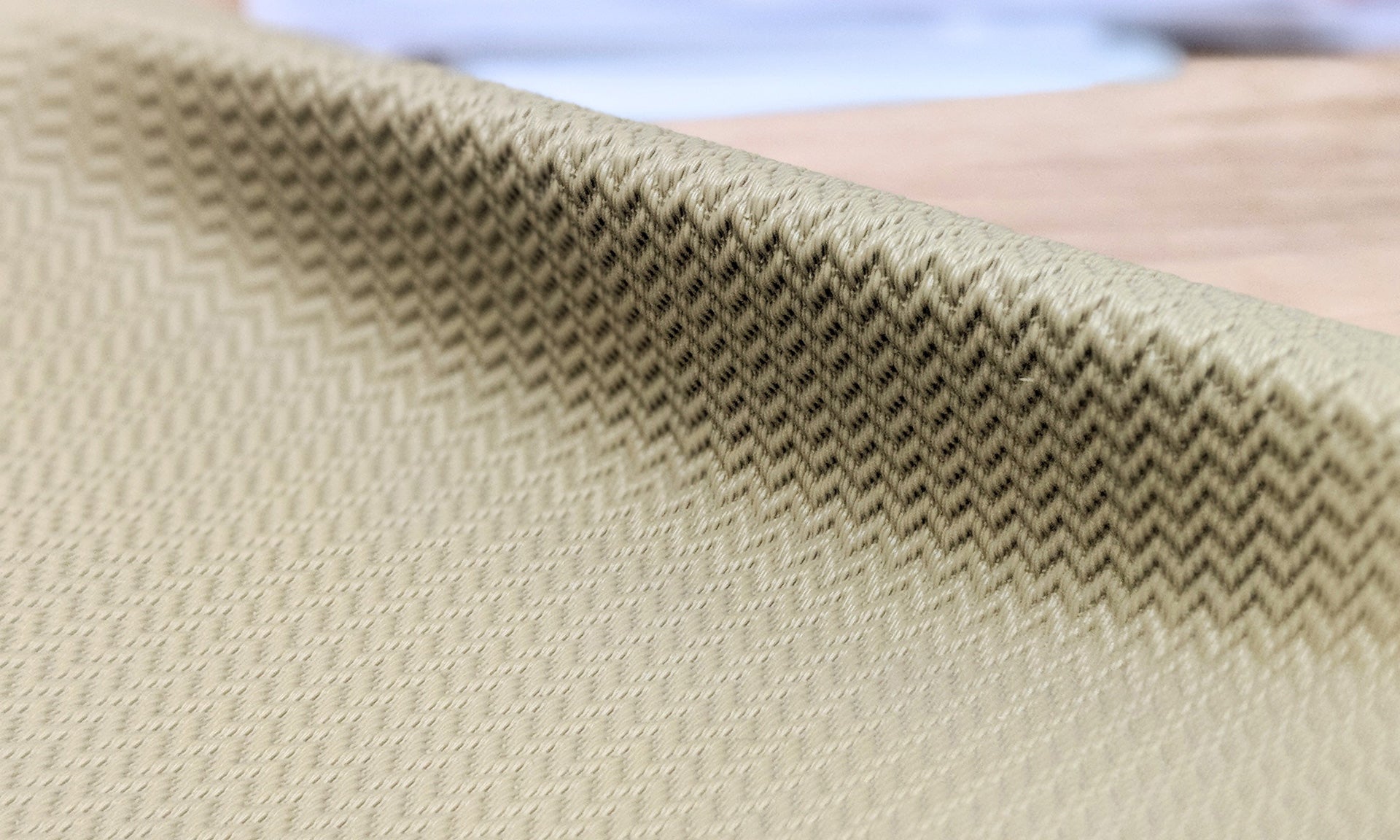

The Ramen luminaires, for example, are generated from an algorithmic process that uses the thick deposited layers to generate the exquisite surface texture. Instead of the fighting the printer's resolution we used it to our advantage. In other cases, we focus on the material, such as using cellulose fibers in the plastic to create a texture that diminishes the visibility of layers. Creatively applying this technology is what we wake in the morning thinking about.

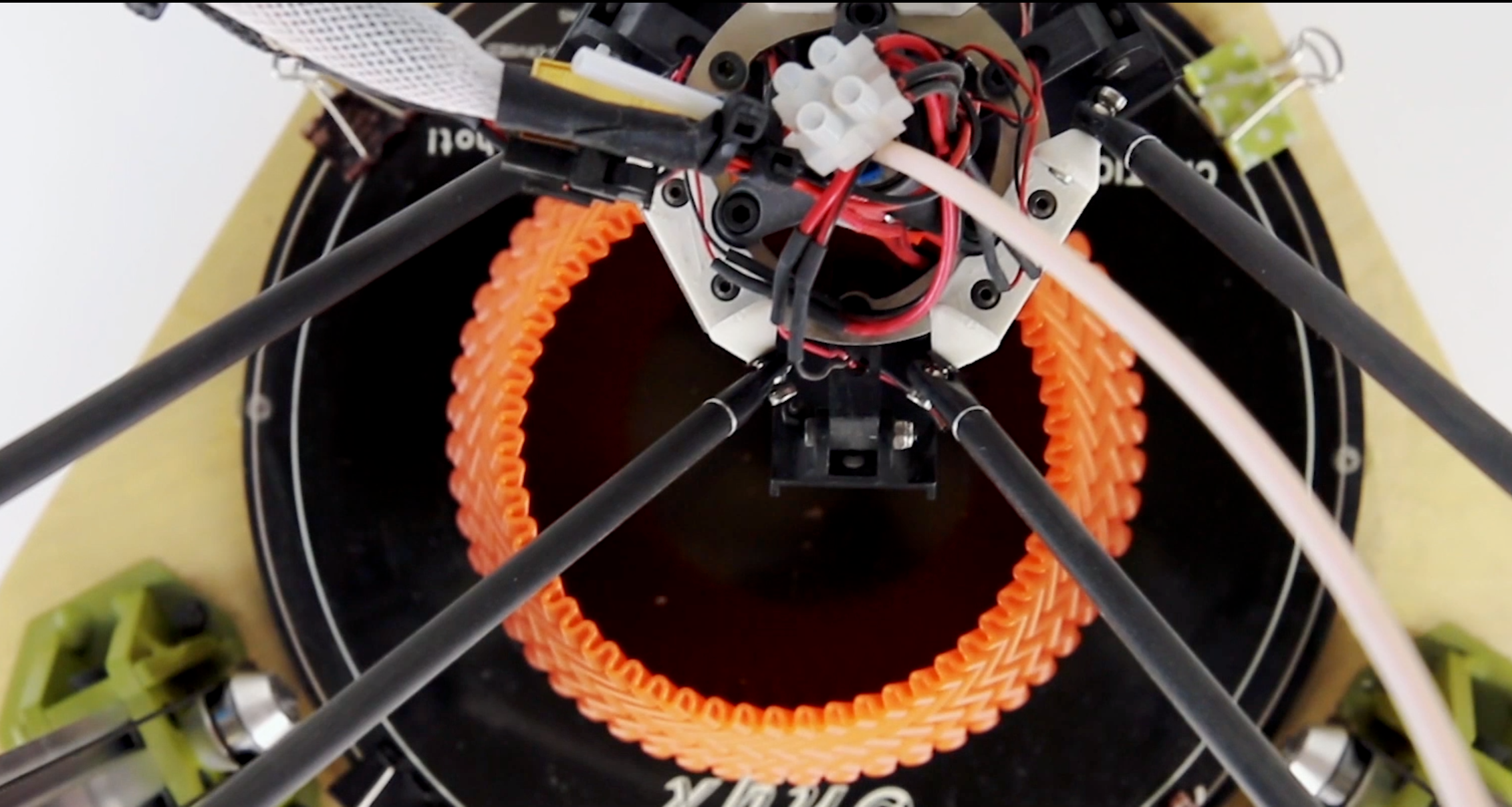

We owe a debt of gratitude to the RepRap Project. Without the RepRap Project, we wouldn't have desktop 3D printing like we do today. They removed the barrier to entry by making the technology open-source and affordable. This noble gesture sparked a huge community of inspired people that continues today, pushing 3D printing to be cheaper, better, reliable, versatile, and accessible. Our founder, Guy Snover, has been tinkering with 3D printers since the first MakerBot was released. He designs and builds the printers we use. Years of hands-on experience with the printers allows him to build custom printers tailored to a specific product or technique. A 3D printer is just a tool; masters make their own tools.